OVERVIEW

The heating, ventilation and air–conditioning (HVAC) industry is in the midst of a dynamic era, however air–distribution ductwork remains virtually unchanged since the early 1900s.

Several factors have introduced the need to revolutionize HVAC ductwork. Energy use has continued to escalate, and thus the demand for energy reducing solutions has intensified. Requirements for clean air are becoming increasingly prevalent. Speed of construction has become a valuable asset. Floor space and headroom are under constant pressure.

Traditionally, HVAC ductwork is constructed from galvanized sheet steel, which is installed first and then insulated separately as a second operation. The Kingspan KoolDuct® System however, is an advanced and innovative pre–insulated rectangular HVAC ductwork system, which is installed in a single–fix.

The Kingspan KoolDuct® System eliminates virtually all of the problems associated with galvanized sheet steel, fiber glass duct board and pre–insulated rigid polyiso (PIR) ductwork systems whilst, at the same time, offering additional advantages to the specifying engineer, the architect, the M&E contractor, the fabricator, the facilities manager, the property developer and the building owner.

Ductwork fabricated from The Kingspan KoolDuct® System can reduce air–leakage rates to a fraction of those typical of rectangular sheet metal ductwork. This cutting edge System thus offers the triple benefits of cutting energy use, cutting operational carbon dioxide (CO2) emissions and cutting costs.

As a result, The Kingspan KoolDuct® System should be considered the ductwork system of choice, where low embodied environmental and low operational environmental impacts are key requirements.

What is The Kingspan KoolDuct® System?

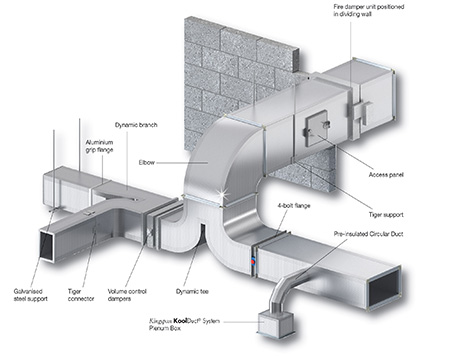

The Kingspan KoolDuct® System comprises premium performance Kingspan KoolDuct® panels, fabrication methods, coupling systems and a complete line of accessories to produce pre–insulated rectangular ductwork in sections up to 13 ft / 3.93 m long.

Kingspan KoolDuct® panels are available in the following standard thicknesses and corresponding installed R–values:

7/8” = R–6.0 ft²·hr·°F/Btu /22 mm = R–1.047 m²·K/W; and

7/8” = R–6.0 ft²·hr·°F/Btu /22 mm = R–1.047 m²·K/W; and

1 3/16” = R–8.1 ft²·hr·°F/Btu /30 mm = R–1.428 m²·K/W.

This allows ductwork to be fabricated with different wall thicknesses to suit different performance specifications. Kingspan KoolDuct® panels comprise a fiber-free rigid thermoset phenolic insulation core faced with branded silver aluminum foil on one side and plain silver aluminum foil on the other.

In addition, there are several coupling systems available to suit different installation and project specification requirements. They include the 4–bolt, aluminum grip and Tiger Clip systems.

The design of ductwork, including fittings, fabricated from The Kingspan KoolDuct® System follows the same calculation principles and duct sizing methods as are used for ductwork constructed from galvanized sheet steel.

Kingspan Insulation offers a complete product line, providing all materials, tools and accessories

necessary for the effective fabrication of ductwork from The Kingspan KoolDuct® System.

What’s Different about The Kingspan KoolDuct® System?

- UL Listed – was the first premium performance pre–insulated ductwork in the world to be UL Listed as a Class 1 Air Duct, to Standard for Safety UL 181 (Underwriters Laboratories: Factory Made Air Ducts & Air Connectors), when fabricated to a specification clearly defined by UL.

- Low weight – weighs up to 72% less than ductwork constructed from galvanized sheet steel and insulated with fiber glass duct wrap – this makes it ideal for refurbishment projects, where existing building structures have insufficient load capacities for new service loads.

- Faster installation speeds – low weight ductwork fabricated in sections up to 13 ft / 3.93 m long, single–fix installation and no need to install insulation as a second operation, reduces project scheduling periods for insulated ductwork.

- Space saving – typically saves up to 6–8” / 150–200 mm in a single dimension, since the space required to manually install a separate layer of insulation around the ductwork is eliminated – this allows ductwork to be installed flush to ceilings, walls and floors, as well as to surfaces within confined enclosures.

- Installed cost savings – reduced labor and materials, including fixings and first level support members, can provide an ideal value engineered ductwork solution without compromising performance – over 16% less expensive.

- Low air–leakage – rates can be reduced to a fraction of those typical of rectangular sheet metal ductwork – can easily achieve SMACNA air–leakage Class 3.

- Reduced energy usage & running costs – low ductwork air–leakage can yield significant electrical consumption savings because of reduced heating and cooling loads, and fan energy usage.

- Easily modified – ductwork configurations can be easily modified and adapted onsite to deal with unexpected changes to the design, which may be required to circumvent unforeseen obstructions and

other building design issues. - Single source supply – Kingspan Insulation offers a complete product line, providing all materials, tools and accessories necessary for the effective fabrication of ductwork, all through a single supplier.

- Easily integrated – into existing sheet metal fabrication workshops with low cost capital investment,and without having to radically extend, reconfigure or retrofit.

- Whole life cost saving – up to 20% over 30 years, compared with ductwork constructed from galvanized sheet steel and insulated with glass fiber duct wrap.

- Lower embodied energy – up to 27% less than that of fiber glass insulated galvanized sheet steel ductwork.

- Reduced operational CO2 emissions – as a result of low ductwork air–leakage, and the subsequent reduction in operational energy usage.

- Reduced workshop–generated waste – computer aided fabrication can greatly reduce the volume of waste, compared with manual fabrication.

- High R–values with thin insulation – the low thermal conductivity (k–value / l–value) of Kingspan KoolDuct® panels makes it the most thermally efficient, and hence the thinnest, insulationproduct commonly used for pre–insulated HVAC ductwork.

- A fiber-free rigid insulation core – minimizes the risk of loose fibers entering the airstream through the ductwork, since distributed air does not come into contact with an insulation material that produces loose fibers.

- Zero–ODP & Low GWP – the insulation core of Kingspan KoolDuct® panels is manufactured with a CFC/HCFC–free blowing agent that has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP).

- LEED® – ductwork fabricated from The Kingspan KoolDuct® System can contribute points towards achieving credits, including pilot credits, in many of the LEED® rating systems.